Once material filling starts, heat blower starts up and material heating begins. Control cabinet would stop sending signals to auto loader when material filling amount is higher than material level switch.

189-4860-6110 / 0769-82020256 Online consultationOnce material filling starts, heat blower starts up and material heating begins. Control cabinet would stop sending signals to auto loader when material filling amount is higher than material level switch. Then material heating lasts for a while. When temperature sensing needle detects the value of reaching the set crystallized temperature, material would be conveyed out via feeding device; meanwhile, as material level in hopper lowers gradually, filling device starts to supply the uncrystallized material accordingly to realize the continuous crystallization process.

When temperature sensing needle detects the temperature value of stopping material conveying, feeding device halts. If temperature rises again to reach the set crystallized temperature, feeding device will be activated to work so that the continuous crystallization process can be realized through this kind of circle.

Naming Principle

Application

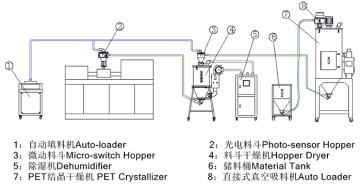

OCR closed-loop crystallizers are used for constant crystallization of un-crystallized TPU regrinds or pellets. Processed materials can then be dried and dehumidified directly. This system mainly consists of heating elements, insulated hopper and agitator screw mixing device. After un-crystallized TPU materials fed into the hopper, the system starts crystallization and agitator starts blending to prevent formation in lumps. Crystallized materials can be conveyed to material storage bin or into drying hopper.

Features

1. Simplify and improve drying efficiency.

2. Fixed speed of agitator makes materials not lump together during the crystallization.

3. Materials can be dried under high temperature to improve drying efficiency.

4. Cyclone dust collector is optional equipped, which is applied to dust-rich place. Can effectively reduce the load on filter bag, and reduce the numbers of filter bag cleaning, thus extend the life span of the filter bag.

5. With double overheat protector, it can reduce the possibility of either mechanical or man-made problems.

6. Equipped with rotary valve with good sealing performance, which can output crystallized material accurately.

7. Equipped with material level switch, which can detect material level accurately and make operation reliable.

Parameters

PET Properties

PET material is widely-used in textile fiber, food and chemical packaging, tape stripes, industry thread, heat-resistant dishware. Air bubble and chapping will take place due to its high moisture content.

With this drying demand and the development on plastic industry, Orste provides a series of secured and reliable drying and dehumidifying technologies for PET molding and other PET product manufacturers.

Orste’s PET system has advanced technology to meet various application needs: Bottle and blank making, Thermal forming film and sheet making, Strapping tape and industrial yarns making, Tubing making, Waste recovery making and other similar fields.